Japanese / English

“Leave your automotive and electronic device harnesses to Fuji Denki Kogyo.”

High-speed crimping technology using automatic crimping machine

Sophisticated crimping certified worker

We utilize approximately 65 years of know-how to maintain quality in crimping wires and terminals, which is the lifeblood of harnesses.

Crimping equipment and finished dimensions are carefully managed by certified workers.

Crimping equipment and finished dimensions are carefully managed by certified workers.

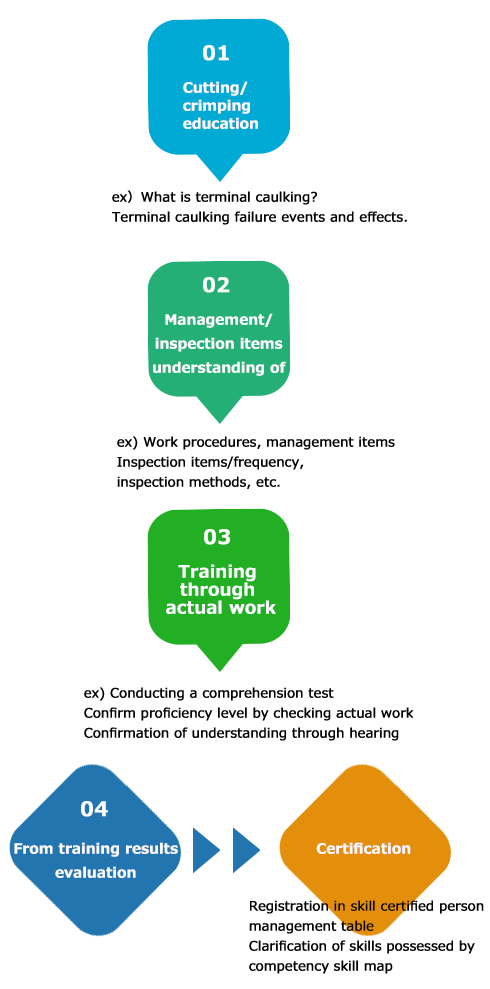

Cutting/crimping operator certification flow

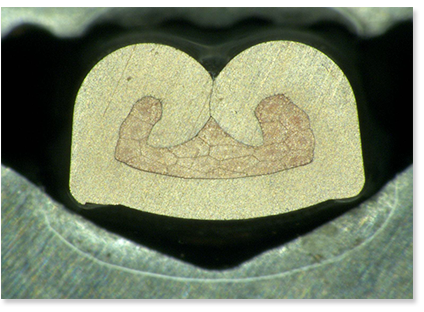

Cross-sectional evaluation using a polisher/microscope

In addition to crimping dimensions, we also cut and evaluate the cross section after crimping.

Comes with compression ratio measuring device

Wire harness production flow

Equipment introduction

cutting machining

~Specialist Dispatch Program in Overseas~

One of our two specialists is always stationed at our overseas base and provides independent support for technology, quality, and production technology.

Production equipment technical guidance

Vietnam factory quality study session

Initiatives towards SDGs

・Independence support for people with disabilities

・In-house and external education using unique educational programs and educational tools

(Quality education for newcomers and direct technical education from professional engineers for people with disabilities)

・Harassment prevention activities

・Implementation of medium- and short-term management plans

・Installation of barrier-free toilets for people with disabilities

・Establishment of a rest room for people with disabilities

・Transportation arrangements for people with disabilities

・Use of solar energy for power generation

・Local cleaning activities

・Health and welfare activities, regular health checkups

・XRF, ICP inspection

・Increase the number of female managers